Cost of Warranty

Real story

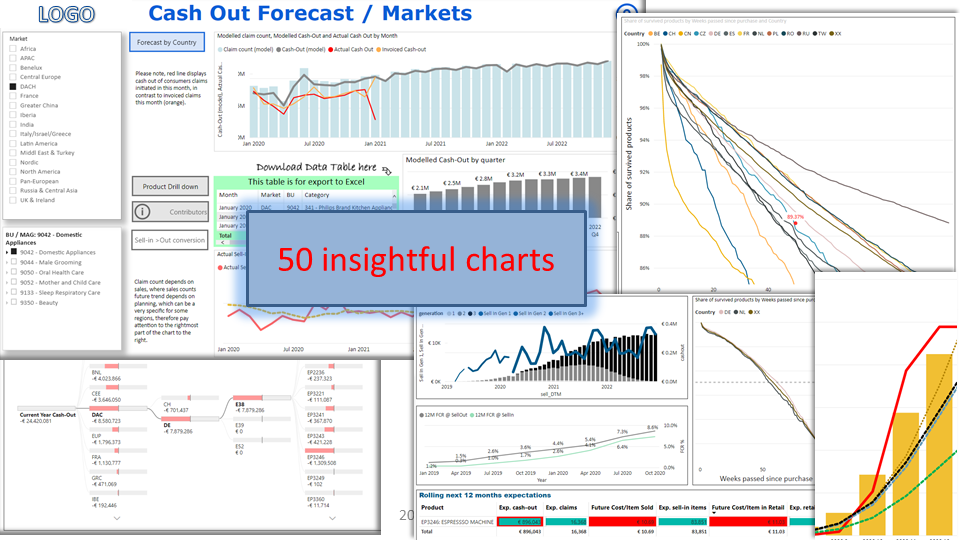

Once upon a time, I got a request from my colleague from the Finance Department to help with forecasts of CoNQ (Cost of Non-Quality) for B2C business unit. Specifically, she spoke about warranty costs.

What is warranty cost from financial perspective? In a simple words, a company that manufactures consumer electronics must make a provision to be able compensate all future warranty costs of products they sell.

Thus, company must know the future cost. The general financial forecasting approach in a big company is a high-level initial prediction; this usually compensates all fluctuations in time series over products. The company assumes that overall business will grow according to a one-year plan (i.e. average 5% sales increase). Therefore, it is possible to replicate the costs from the previous 12 months with 5% uplift. Or, 10% to be on the safe side.

This approach sounds pretty simple and safe unless you think about the impact in absolute figures. Let's say, a company spent 50M Euro on warranty costs worldwide, on all 10 thousand SKUs. It must make a provision of 52.5M for next year (+5%) (or, as it was said, better 55M / +10%), meaning that 55M Euro will be blocked and can't be spent on other needs. If the company underestimated costs, it must occasionally reallocate delta from some other business unit at the end of the year (while, you know, all budgets were already approved and allocated to other needs). If the company overestimated, this delta will be returned back, however, that means that the delta didn't work for the company all the year, and this money (millions of Euro) was not spent on business development or product innovations. More of that, this amount probably will be taxed. This makes the right forecast important.

Well, so how can we improve the quality of the forecast? To come up with ideas, you need to understand first the complexity of this task.

All products are different. Even a small screw can behave differently in two models of an iron. And, surprise-surprise, products behave differently in various countries: cheap shaver can be thrown away in Germany, while it is always claimed in India; the same hairdryer in Korea has different failures than in the USA.

Then, what is extremely important, the warranty cost does not depend on the current-year sales.The cost a company pays this month depends on 3 lagging factors: a) Sales to consumers in the previous 2 years (length of warranty); b) delays in product distribution network; c) delays in spare parts distribution. The same dependency is valid for all future months. Can you imagine the failure of a product invoiced to the company today, manufactured 5 years ago? It is what happens in reality.

Warranty cost significantly depends on product quality improvements, both in the past and planned for the future. It was significantly impacted by various country-wide political/ economic/ epidemic issues, e.g. covid: repair shops were closed and therefore consumers were unable to claim. Retailers were unable to respond to the total switch to online sales platforms and therefore a significant part of the stock was not sold at all.

There is no need to tell about all general data issues: errors in master dictionaries, records made by repair workshops do not contain all the required dates, etc.

Then, as soon as it comes to forecasts, your model depends on sales plans that are not always provided on time and with expected accuracy.

It seems, the obvious proposal can be to evaluate each SKU separately and predict its behaviour on the level of a country. Well, now we can decompose our task into several steps: We have to do research on how sell-in (sales from the manufacturing company) is delayed in a retail network. Just to give you a hint: this is a separate study, and in some cases, the time between sell-in to sell-out (from retailer to consumer) reaches 24 months. Then, we need to invent a way how to deal with quality improvements / deterioration of an SKU. The issue here is in the fact that SKU ID is not changed after this improvement (even in case of significant impact on the quality of the final product) so we do not know what particular product was claimed, and what product is on the shelf of retailer now. Then, we should understand how to deal with late invoices: a failure had been claimed but the item was not repaired yet because the workshop is waiting for spare parts, or the master had a hangover, or occasionally covid-19 happened.

Finally, we come to Machine Learning. Easiest part. Apply Kaplan-Meier survival analysis as everyone does. Oh, no! All products are different! And... all countries are different too. Despite the fact that we are able to use a 10-year history of sales of 10000 SKUs in 50 countries, we still do not have enough data for recently introduced product models. So what to do? How to manage generalization and substitution?